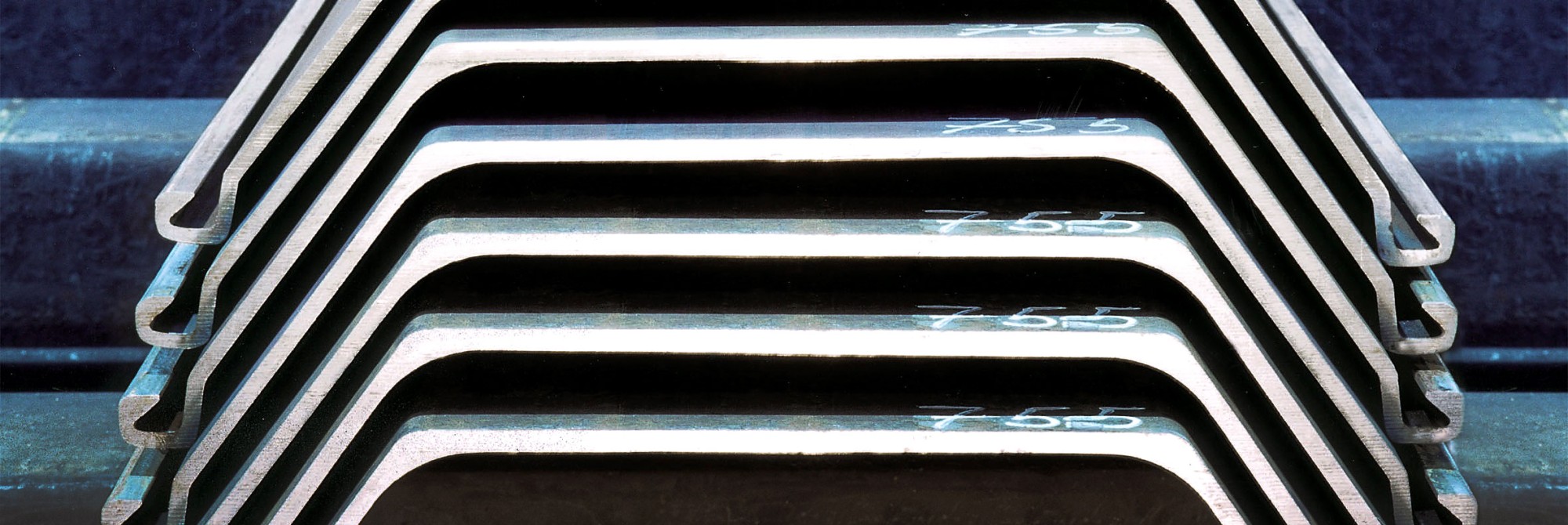

Hot-rolled sheet pile sections

High construction rigidity, very good drive properties, high section modulus: hot-rolled sheet piling

Due to their excellent properties, our hotrolled sheet piling is primarily used in water, road, and civil engineering applications. Hot-rolled pile sections are made from a primary material that is heated to over 1,200 degrees. Different section shapes are possible thanks to the high plasticity of the steel.

U-sections

Our U-sections have excellent structural properties. These high-quality pile sections drive in extremely well. The wide range of available sections allows for use in so many different areas, such as marine engineering, embankment protection, and road engineering, and even in trench shoring.

Applications in construction

- Marine engineering

- Structures for waterways and watercourses

- Embankment protection

- Transport infrastructure construction

- Trench shoring

- Excavations

Z-sections

The continuous web in the sheet piling and the external interlocks are the key features of Z-sections. Both factors have a positive effect on the section modulus in the sheet pile –at relatively low weight. That results in high cost efficiency.

Advantages

The interlock connection is positioned in the area with the lowest shear forces The external LARSSEN lock facilitates an extremely favorable weight–section modulus ratio The tall installation heights of the sections lead to high rigidity values, which limit deflection and allow for higher steel products to be selected

LARSSEN steel piles

LARSSEN steel piles or dolphins are systems for shipping routes and ports. There are different types depending on their use:

- Impact dolphins used to restrict ship travel routes

- Berthing or mooring dolphins used as mooring points for ships

- Navigation dolphins used to guide floating objects such as pontoons or floating docks

Steel beams

Walers made from wide flange beams are used in various shoring methods. They include vertical shoring, which consists of trench sheeting sections / lightweight sections, struts, walers and waler attachments. The waling in these cases consists of the wide flange beam HEB 140-300 depending on strut spacing and structural requirements.

In another method using timber sheet piles and pile locks, the so-called beam-pile wall, both wide flange beams and U-channels are used in a size range from 200-300.

Combined steel sheet piling

Our combined steel sheet piling consists of load-bearing and intermediate piles and is used especially in heavy-duty marine engineering projects on the coast, including marine applications such as quay walls, piers, dock structures, and ro-ro vessels. The combined piles are also used in sluices, dams, inland ports, landfills, and abutments.